Products

Well-designed High Quality HPMC Chemicals 99.9% Hydroxypropyl Methyl Cellulose Manufacturer

Assume full obligation to meet all demands of our customers; accomplish ongoing advancements by promoting the advancement of our customers; become the final permanent cooperative partner of clientele and maximize the interests of shoppers for Well-designed High Quality HPMC Chemicals 99.9% Hydroxypropyl Methyl Cellulose Manufacturer, We welcome consumers, business enterprise associations and friends from all elements of your world to get in touch with us and look for cooperation for mutual rewards.

Assume full obligation to meet all demands of our customers; accomplish ongoing advancements by promoting the advancement of our customers; become the final permanent cooperative partner of clientele and maximize the interests of shoppers for 9004-65-3, C18H38O14, China HPMC, HEC, HEMC, Hydroxypropyl Methyl Cellulose, Hydroxypropyl Methylcellulose, Our company has already have pass the ISO standard and we are fully respect our customer ‘s patents and copyrights. If the customer provides their own designs, We will guarantee that they will likely be the only one can have that goods. We hoping that with our good solutions can bring our customers a great fortune.

Hydroxypropyl Methyl Cellulose HPMC F60S For Cement Based Tile Adhesive Mortar cps 400-200,000

Introduction

Hydroxypropyl methylcellulose (HPMC) are odorless, tasteless,non-toxic cellulose ethers that have had hyrdroxyl groups on the cellulose chain substituted for a methoxy or hydroxypropyl group with good water solubility. HPMC F60S is high-viscosity grade which is used as a thickener, binder, and film former in agrochemicals, coatings, ceramics, adhesives, inks, and various other applications.

Indicators

Product Specifications

| Items&Specifications | HPMC F60S |

| Appearance | White/Off-white Powder |

| Moisture | <5% |

| Ash Content | <5% |

| Gel Temp. | 58-64℃ |

| Methoxy Content | 28-30% |

| Hydroxypropyl Content | 7-12% |

| pH | 6-8 |

| Particle Size | 90% pass 80 mesh |

| Viscosity | 185,000-215,000 mPa.s (NDJ-1, 2% solution, 20℃) |

| 65,000-80,000 mPa.s (Brookfield-RV, 2% solution, 20℃) |

Typical Properties:

| Delayed solubility(surface treated) | NO |

| Sag Resistance | Excellent |

| Consistency Development | Very Fast |

| Open Time | Long |

| Final Consistency | Very High |

| Heat Resistance | Standard |

Construction:

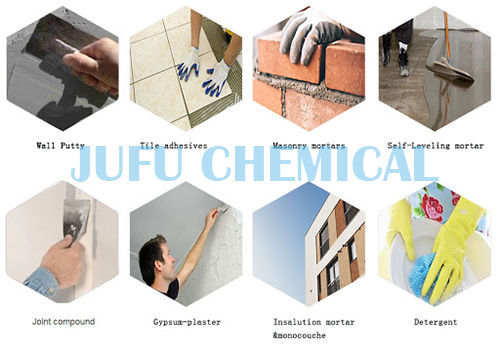

1.Tile adhesives (highly recommend)

2.EIFS/EITCS

3. Skim coat/ Wall putty

4. Gypsum plast

Package&Storage:

Package: 25kg paper plastic bags with PP liner. Alternative package may be available upon request.

Storage: Shelf-life time is 1 year if kept in cool, dried place.Test should be done after expiration.