Products

ODM Supplier Top Quality Hydroxypropyl Methylcellulose HPMC K100m CAS 9004-65-3 for Thickener

“Control the quality by the details, show the power by quality”. Our enterprise has strived to establish a remarkably efficient and stable team team and explored an effective excellent control system for ODM Supplier Top Quality Hydroxypropyl Methylcellulose HPMC K100m CAS 9004-65-3 for Thickener, In case you have any reviews about our organization or goods, be sure to experience totally free to speak to us, your coming mail is going to be very appreciated.

“Control the quality by the details, show the power by quality”. Our enterprise has strived to establish a remarkably efficient and stable team team and explored an effective excellent control system for Celluloses, China HPMC, Dry Mortar, HEMC, Hydroxypropyl Methyl Cellulose, Hydroxypropyl Methylcellulose, Mhpc, Many years of work experience, we now have realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question issues they do not understand. We break down those people barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

Hydroxypropyl Methyl Cellulose HPMC F60S For Cement Based Tile Adhesive Mortar cps 400-200,000

Introduction

Hydroxypropyl methylcellulose (HPMC) are odorless, tasteless,non-toxic cellulose ethers that have had hyrdroxyl groups on the cellulose chain substituted for a methoxy or hydroxypropyl group with good water solubility. HPMC F60S is high-viscosity grade which is used as a thickener, binder, and film former in agrochemicals, coatings, ceramics, adhesives, inks, and various other applications.

Indicators

Product Specifications

| Items&Specifications | HPMC F60S |

| Appearance | White/Off-white Powder |

| Moisture | <5% |

| Ash Content | <5% |

| Gel Temp. | 58-64℃ |

| Methoxy Content | 28-30% |

| Hydroxypropyl Content | 7-12% |

| pH | 6-8 |

| Particle Size | 90% pass 80 mesh |

| Viscosity | 185,000-215,000 mPa.s (NDJ-1, 2% solution, 20℃) |

| 65,000-80,000 mPa.s (Brookfield-RV, 2% solution, 20℃) |

Typical Properties:

| Delayed solubility(surface treated) | NO |

| Sag Resistance | Excellent |

| Consistency Development | Very Fast |

| Open Time | Long |

| Final Consistency | Very High |

| Heat Resistance | Standard |

Construction:

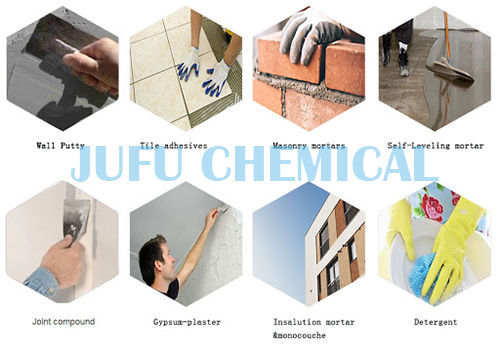

1.Tile adhesives (highly recommend)

2.EIFS/EITCS

3. Skim coat/ Wall putty

4. Gypsum plast

Package&Storage:

Package: 25kg paper plastic bags with PP liner. Alternative package may be available upon request.

Storage: Shelf-life time is 1 year if kept in cool, dried place.Test should be done after expiration.