Post Date: 14,Mar,2022

An admixture is defined as a material other than water, aggregates, hydraulic cementitious material or fiber reinforcement that is used as an ingredient of a cementitious mixture to modify its freshly mixed, setting or hardened properties and that is added to the batch before or during mixing. As noted in Part 1, a chemical admixture is usually further defined as a nonpozzolanic (does not require calcium hydroxide to react) admixture in the form of a liquid, suspension or water-soluble solid.

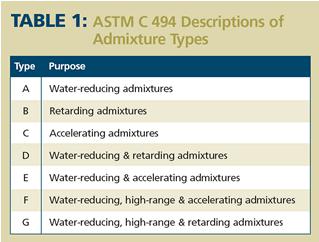

Water-reducing admixtures improve concrete’s plastic (wet) and hardened properties, while set-controlling admixtures are used in concrete being placed and finished in other than optimum temperatures. Both, when used appropriately, contribute to good concreting practices. Also, both admixtures should meet the requirements of ASTM C 494 (see Table 1).

Water-Reducing Admixtures

Water reducers do essentially that: reduce the amount of mixing water required to obtain a given slump. This can result in a reduction of the water-cementitious ratio (w/c ratio), which leads to increased strengths and more durable concrete.

Reducing the w/c ratio of concrete has been identified as the most important factor to making durable, high-quality concrete. On the other hand, sometimes the cement content may be lowered while maintaining the original w/c ratio to reduce costs or the heat of hydration for mass concrete pours.

Water-reducing admixtures also reduce segregation and improve the flowability of the concrete. Therefore, they are commonly used for concrete pumping applications as well.

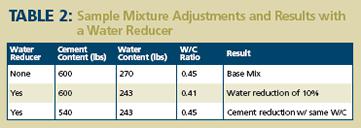

Water-reducing admixtures typically fall into three groups: low-, medium- and high-range. These groups are based on the range of water reduction for the admixture. The percent of water reduction is relative to the original mix water required to obtain a given slump (see Table 2).

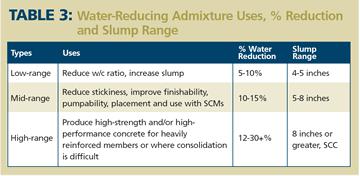

While all water reducers have similarities, each has an appropriate application for which it is best suited. Table 3 presents a summary of the three types of water-reducing admixtures, their ranges of water reduction and their primary uses. Their effect on air entrainment will vary depending on the chemistry.

How they work

When cement comes in contact with water, dissimilar electrical charges at the surface of the cement particles attract one another, which results in flocculation or grouping of the particles. A good portion of the water is absorbed in this process, thereby leading to a cohesive mix and reduced slump.

Water-reducing admixtures essentially neutralize surface charges on solid particles and cause all surfaces to carry like charges. Since particles with like charges repel each other, they reduce flocculation of the cement particles and allow for better dispersion. They also reduce the viscosity of the paste, resulting in a greater slump.

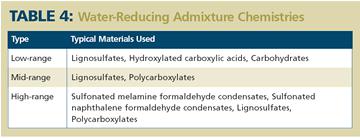

Table 4 presents some of the most common materials used for each range of water reducer. Other components are also added depending on the product and manufacturer. Some water-reducing admixtures have secondary effects or are combined with retarders or accelerators.

Post time: Mar-14-2022