Hot Weather

Under hot weather conditions, emphasis is placed on managing concrete setting times and minimizing moisture loss from the placement. The simplest way to summarize hot weather recommendations for topping construction is to work in stages (pre-placement, placement, and post-placement).

Hot weather considerations in the pre-placement stage include construction planning, concrete mixture design, and base slab conditioning. Concrete topping mixtures designed with a low bleed rate are particularly susceptible to common hot weather issues such as plastic shrinkage, crusting, and inconsistent setting time. These mixtures generally have a low water-cementitious materials ratio (w/cm) and high fines content from aggregate and fibers. Using a well-graded aggregate with the largest top size possible for the application is always advisable. This will improve water demand and workability for a given water content.

Conditioning of the base slab is one of the most important considerations when placing toppings in hot weather. Conditioning will vary depending on the topping design. Bonded toppings benefit from both temperature and moisture conditioning while only temperature conditions would be necessary to consider for unbonded slabs.

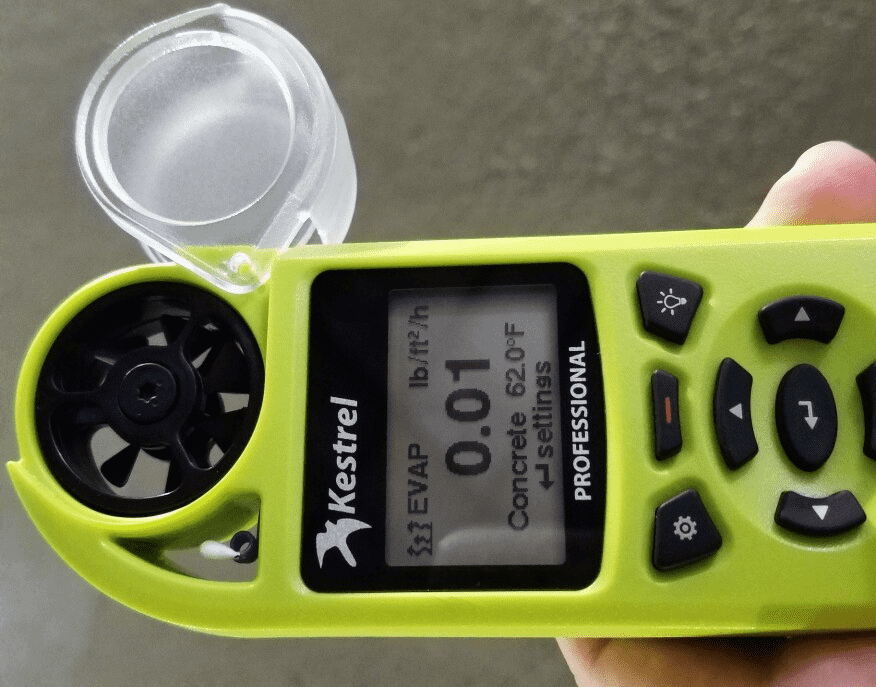

Some portable weather stations measure ambient conditions and allow input of the concrete temperature to provide the evaporation rate during concrete placement.

Base slab moisture conditioning for bonded toppings reduces moisture loss from the topping and can help prolong the setting time of the topping mixture by cooling the base slab. There is no standard procedure for conditioning a base slab and no standard test method for evaluating the surface moisture level of a base slab ready to receive a topping. Contractors surveyed about their base-slab hot-weather preparation reported a range of successful conditioning methods.

Some contractors wet the surface with a garden hose while others like to use a pressure washer to help clean and force water into surface pores. After wetting the surface, contractors report a wide variation in soaking or conditioning times. Some contractors that use power washers proceed with topping placement immediately after wetting and removal of excess water from the surface. Depending on ambient drying conditions, others will wet the surface more than once or cover the surface with plastic and condition it for between two and 24 hours prior to removing excess water and placing the topping mixture.

The temperature of the base slab may also need conditioning if it is substantially warmer than the topping mix. A hot base slab can negatively impact the topping mix by reducing its workability, increasing water demand, and accelerating setting time. Temperature conditioning can be difficult based on the mass of the existing slab. Unless the slab is enclosed or shaded, there are few alternatives for reducing base slab temperature. Contractors in the southern U.S. prefer wetting down the surface with cool water or placing the topping mix at night or both. Contractors surveyed did not limit topping placements based on substrate temperature; most preferred night placements and moisture conditioning, based on experience. In a study of bonded pavement overlays in Texas, researchers reported base slab temperatures of 140 F or higher during summer in direct sunlight and recommended avoiding topping placements when substrate temperatures were more than 125 F.

Hot weather considerations in the placement stage include managing concrete delivery temperatures and moisture loss from the topping slab during the finishing process. The same procedures used to manage concrete temperature for slabs can be followed for toppings.

In addition, moisture loss from a concrete topping should be monitored and minimized. Rather than using online evaporation-rate estimators or nearby weather station data to calculate the evaporation rate, a handheld weather station should be positioned at a height of about 20 inches above the slab surface. Equipment is available that can measure the ambient air temperature and relative humidity as well as the wind speed. These devices only need to have the concrete temperature entered to automatically calculate the evaporation rate. When the evaporation rate exceeds 0.15 to 0.2 lb/sf/hr, action should be taken to decrease the evaporation rate from the topping surface.

Post time: Apr-06-2022