Post Date:1,Apr,2024

It is generally believed that the higher the temperature, the more the cement particles will adsorb the polycarboxylate water-reducing agent. At the same time, the higher the temperature, the more obvious the cement hydration products will consume the polycarboxylate water-reducing agent. Under the combined influence of the two effects, as the temperature increases, the fluidity of concrete becomes worse. This conclusion can well explain the phenomenon that the fluidity of concrete increases when the temperature suddenly drops, and the slump loss of concrete increases when the temperature rises. However, during construction, it was found that the fluidity of concrete is poor at low temperatures, and when the temperature of the mixing water is increased, the fluidity of the concrete after the machine is increased. This cannot be explained by the above conclusion. To this end, experiments are conducted to analyze, find out the reasons for the contradiction, and provide the appropriate temperature range for concrete.

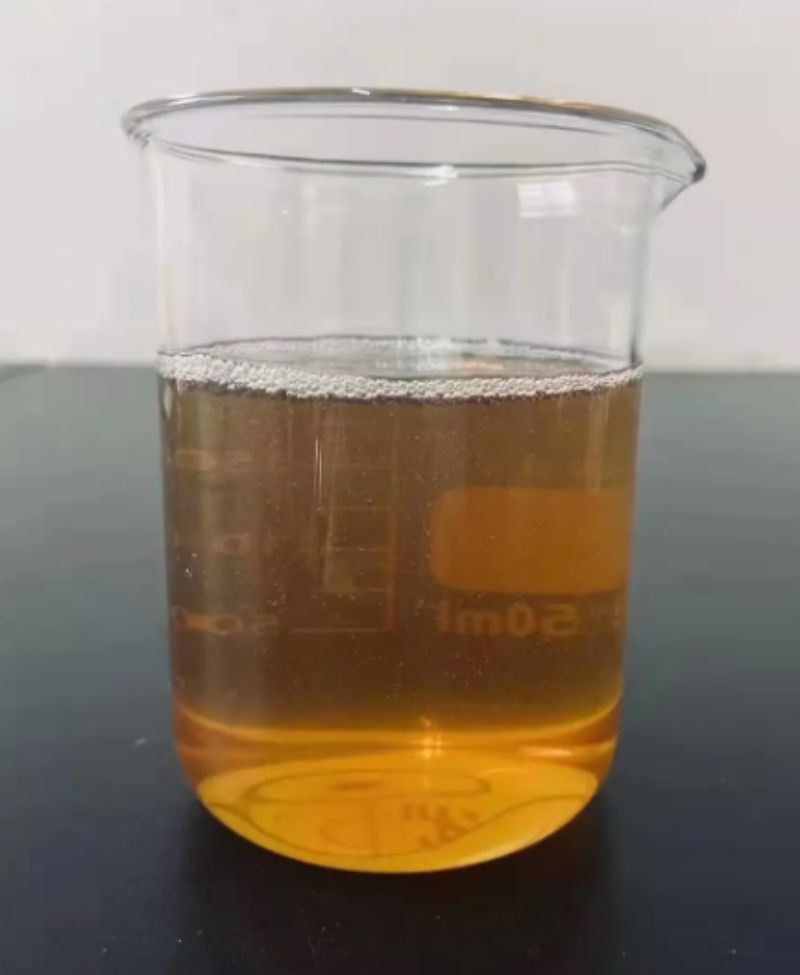

In order to study the effect of mixing water temperature on the dispersion effect of polycarboxylate water-reducing agent. Water at 0°C, 10°C, 20°C, 30°C, and 40°C was prepared respectively for cement-superplasticizer compatibility test.

Analysis shows that when the out-of-machine time is short, the expansion of cement slurry first increases and then decreases as the temperature increases. The reason for this phenomenon is that temperature affects both the cement hydration rate and the adsorption rate of the superplasticizer. When the temperature rises, the faster the adsorption rate of superplasticizer molecules is, the better the early dispersion effect will be. At the same time, the hydration rate of cement accelerates, and the consumption of water-reducing agent by hydration products increases, which reduces the fluidity. The initial expansion of cement paste is affected by the combined effect of these two factors.

When the mixing water temperature is ≤10°C, the adsorption rate of the superplasticizer and the cement hydration rate are both small. Among them, the adsorption of water-reducing agent on cement particles is the controlling factor. Since the adsorption of water-reducing agent on cement particles is slow when the temperature is low, the initial water-reducing rate is low, which is manifested in the low initial fluidity of cement slurry.

When the temperature of the mixing water is between 20 and 30°C, the adsorption rate of the water-reducing agent and the hydration rate of the cement increase at the same time, and the adsorption rate of the water-reducing agent molecules increases more obviously, which is reflected in the increase in the initial fluidity of the cement slurry. When the mixing water temperature is ≥40°C, the cement hydration rate increases significantly and gradually becomes a controlling factor. As a result, the net adsorption rate of water-reducing agent molecules (adsorption rate minus consumption rate) decreases, and the cement slurry also shows insufficient water reduction. Therefore, it is believed that the initial dispersion effect of the water reducing agent is best when the mixing water is between 20 and 30°C and the cement slurry temperature is between 18 and 22°C.

When the out-of-machine time is long, the cement slurry expansion is consistent with the generally accepted conclusion. When time is sufficient, the polycarboxylate water-reducing agent can be adsorbed on the cement particles at each temperature until it is saturated. However, at low temperatures, less water-reducing agent is consumed for cement hydration. Therefore, as time goes by, the expansion of the cement slurry will increase with temperature. Increase and decrease.

This test not only considers the temperature effect, but also pays attention to the effect of time on the dispersion effect of polycarboxylate water-reducing agent, making the conclusion more specific and closer to engineering reality. The conclusions drawn are as follows:

(1) At low temperatures, the dispersion effect of polycarboxylate water-reducing agent has obvious timeliness. As the mixing time increases, the fluidity of the cement slurry increases. As the temperature of the mixing water increases, the expansion of the cement slurry first increases and then decreases. There can be significant differences between the state of concrete as it comes out of the machine and the state of the concrete as it is poured on site.

(2) During low-temperature construction, heating the mixing water can help improve the fluidity lag of concrete. During construction, attention should be paid to the control of water temperature. The temperature of the cement slurry is between 18 and 22°C, and the fluidity is the best when it comes out of the machine. Prevent the phenomenon of reduced fluidity of concrete caused by excessive water temperature.

(3) When the out-of-machine time is long, the expansion of cement slurry decreases as the temperature increases.

Post time: Apr-01-2024