Products

Manufacturer of Redispersible Polymer Powder Vae/Rdp for Cement Based Tile Adhesive Mortars Additives

We constantly think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body along with the living for Manufacturer of Redispersible Polymer Powder Vae/Rdp for Cement Based Tile Adhesive Mortars Additives, Accurate process devices, Advanced Injection Molding Equipment, Equipment assembly line, labs and software progress are our distinguishing feature.

We constantly think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body along with the living for China Rdp Powder, Redispersible Emulsion Powder, Redispersible Latex Powder, Redispersible Polymer Powder, Redispersible Rubble Powder, We always hold on the company’s principle “honest, professional, effective and innovation”, and missions of: allow all drivers enjoy their driving at night, let our employees can realize their value of life, and to be stronger and service more people. We have been determined to become the integrator of our product market and one-stop service provider of our product market.

Redispersible Polymer Powder

Introduction

RDP 2000 improves adhesion, flexural strength, abrasion resistance and workability of modified compounds such as tile adhesives, self-leveling compounds and gypsum based compounds. It is therefore compatible with mortar additives used to achieve special processing characteristics.

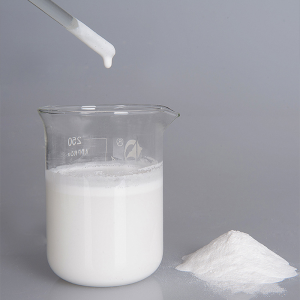

RDP 2000 contains a fine, mineral filler as anti-block agent. It is free of solvents, plasticizers and film-forming aids.

Indicators

Product Specifications

| Solid Content | >99.0% |

| Ash content | 10±2% |

| Appearance | White Powder |

| Tg | 5℃ |

Typical Proerty

| Polymer Type | VinylAcetate-Ethylene copolymer |

| Protective Colloid | Polyvinyl Alcohol |

| Bulk Density | 400-600kg/m³ |

| Average Particle Size | 90μm |

| Min Film Forming Temp. | 5℃ |

| pH | 7-9 |

Construction:

1.0Exterior Thermal Insulation System(EIFS)

Tile Adhensive

2. Grouts/Joint Mixture

3. Binding Mortar

4.Water-proofing/Repairing Mortars

Package&Storage:

Package: 25kg paper plastic bags with PP liner. Alternative package may be available upon request.

Storage: Shelf-life time is 1 year if kept in cool, dried place.Test should be done after expiration.