Products

Low MOQ for China Sika Concrete Admixture Replacement Polycarboxylate Set Retarder, PCE Mother Liquid 50%

carry on to boost, to guarantee products excellent in line with market and consumer standard specifications. Our enterprise has a quality assurance system are actually established for Low MOQ for China Sika Concrete Admixture Replacement Polycarboxylate Set Retarder, PCE Mother Liquid 50%, Seeing believes! We sincerely welcome the new customers abroad to set up business relationships and also expect to consolidate the relationships with the long-established customers.

carry on to boost, to guarantee products excellent in line with market and consumer standard specifications. Our enterprise has a quality assurance system are actually established for China Polycarboxylate Superplasticizer, Pce Superplasticizer Slump Attention, Polycarboxylate Ether, Polycarboxylate Superplasticizer, Powder Polycarboxylate Superplasticizer, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which might be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we’ll continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

Polycarboxylate Superplasticizer PCE Liquid Slump Retention Type

Introduction

Polycarboxylate Superplasticizer is a new excogitate environmental superplasticizer. It is a concentrated product, best high water reduction, high slump retention ability, low alkali content for the product, and it having high strength gained rate. At the same time, it also can improve the plastic index of fresh concrete, so as to improve the performance of concrete pumping in construction. It can be widely used in premix of common concrete, gushing concrete, high strength and durability concrete. Especially! It can be used in high strength and durability concrete having excellent capability.

Indicators

|

Item |

Specification |

|

Appearance |

light yellow or white liquid |

|

Solid content |

40% / 50% |

|

Water reducing agent |

≥25% |

|

pH value |

6.5-8.5 |

|

Density |

1.10±0.01 g/cm3 |

|

Initial seting time |

-90 – +90 min. |

|

Chloride |

≤0.02% |

|

Na2SO4 |

≤0.2% |

|

Cement paste fluidity |

≥280mm |

Physical & mechanical properties

|

Test Items |

Specification |

Test Result |

|

|

Water Reducing Rate(%) |

≥25 |

30 |

|

|

Ratio of bleeding rate at normal pressure(%) |

≤60 |

0 |

|

|

Air Content(%) |

≤5.0 |

2.5 |

|

|

Slump retention value mm |

≥150 |

200 |

|

|

Ratio of Compressive Strength(%) |

1d |

≥170 |

243 |

|

3d |

≥160 |

240 |

|

|

7d |

≥150 |

220 |

|

|

28d |

≥135 |

190 |

|

|

Ritio of Shrinkage(%) |

28d |

≤105 |

102 |

|

Corrosion of reinforcing steel bar |

None |

None |

|

Application

1. High water reduction: Excellent dispersion can provide a strong water reduction effect,the water reduction rate of concrete is more than 40%, it provide a guarantee to improve the performance and strength of concrete, saving cement.

2.Easying to control production: Controling water reduction ratio, plasticity and air entraining by adjusting molecular weight of main chain, length and density of side chain, type of side chain group.

3. High slump retention ability: Excellent slump retention ability, especially has good performance in the low slump maintain, to ensure the performance of concrete, without affecting the normal condensation of concrete.

4.Good adhesion: Making concrete have excellent workability, Non-layer, without segregation and bleeding.

5. Ecellent workability: High fluidity, easily deposing and compacting, to make concrete reducing viscosity, without bleeding and segregation, easily pumping.

6.High strength gained rate: Greatly increasing early and after strength, reducing energy loss. Reduction of cracking, shrinkage and creep.

7. Wide adaptability: It is compatible with ordinary silicate cement, silicate cement, slag silicate cement and all kinds of blendings having excellent dispersibility and plasticity

8. Excellent durability: Low lacunarate,Low alkali and chlorin-ion content. Enhancing concrete strength and durability

9. Environmental friendly products: No formaldehyde and other harmful ingredients,No pollution during production.

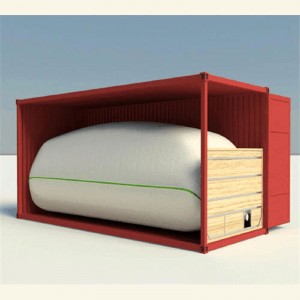

Package:

1. Liquid product: 1000kg tank or flexitank.

2. Stored under 0-35℃, far away from sunlight.