Detuo ụbọchị:17,Jul,2023

Nsogbu ụlọ ọrụ kachasị na nke ime ntụ ntụ ntụ ntụ na-acha ntụ na whitening. Iji ghọta ihe kpatara peeling nke mgbidi dị n'ime, ọ dị mkpa iji ghọta ihe mejupụtara akụrụngwa na ọgwụgwọ nke ntụ ntụ. Mgbe ahụ, dabere na nkụ, ide mmiri, okpomọkụ mmiri nkụ nke mgbidi ahụ, chọpụta ụzọ ihe kpatara nke ahụ na-eme ihe na-eji dozie nsogbu nke ntụ ntụ

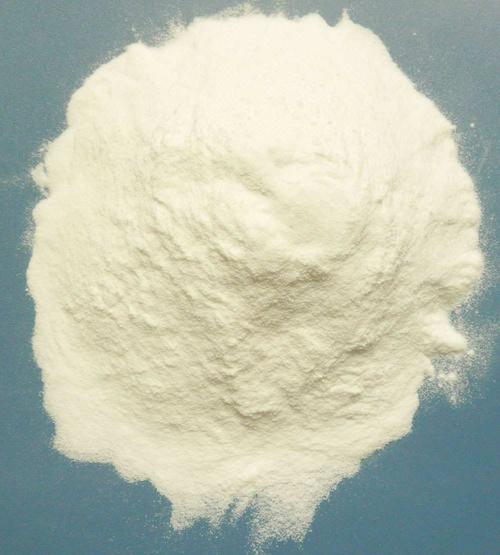

N'ezie, ihe mejupụtara akụrụngwa nke ime mgbidi dị n'ime ntụ ntụ:

Ihe kachasị mkpa nke ime mgbidi ime ntụ ntụ na-agbakwunye: ihe eji eme ihe (awọ na polcium, wdg), na polyvinyl mmanya, wdg.). N'etiti ha, ime mgbidi na ntụ ntụ ntụ ntụ n'ozuzu anaghị agbakwunye ciment ọcha ma ọ bụ naanị na-agbakwunye obere ciment. Ntugharị na-acha uhie uhie nwere obere mmetụta na usoro dị ala, yabụ, ọ naghị eji ya eme ihe na mpaghara ime ụlọ ma ọ bụ nke a na-ejikarị.

N'ihi ya, n'ihi okwu a na usoro nke Mgbidi ime ime Banty ntụ ntụ

1

2. Nkwendị nke njikọ nke otu n'ime polymer na-eri nri dị ala ma ọ bụ na-anaghị ezute ụkpụrụ dị mma nwere ike ibute ntụ ntụ ntụ ntụ ahụ iji daa.

二, na-agwọ usoro nke ime mgbidi dị na Mgbidi ntụ ntụ

Ọgwụ nke mgbidi ime ụlọ ntụ ntụ ntụ ntụ na-adabere na mmetụta nke ọgbụgba nke wayo ga-eme ntụ ntụ, na-etolite ihe nkiri, ma dozie usoro ịgwọ ọrịa.

Isi okwu nke ihe siri ike nke ntụ ntụ na-acha ntụ ntụ:

Ihicha na skal scraping: N'oge a scraping usoro, nnukwu mmiri na-ekusi ike ntụ ntụ, na-akpụ nnukwu netwok nke pores na slurry. Mmiri na-enweghị oghere fọdụrụ na pores, n'ihi nrụgide nke oke mmiri, na-eme ka nrụgide nke ahịhịa, na-eme ntụ ntụ na ntụ ntụ karị na-etolite, si otú ahụ nweta ike. Mgbe slurry ahụ a mịrị amị, a na-ewusi ike a. A na-ekewa crystalking sie ike: nsị na-agbasasị nke colloidal na slurry na-ekewa site na obere akwa dị n'etiti. Dị ka ọdịnaya mmiri nke ji nwayọọ nwayọọ na-ebelata, ma si otú ahụ na-ejide onwe ya n'okpuru ndị agha molecular, na-akpụzi ikike dị iche iche. Carbon Harnang: a slurry na-amachi gas site na ikuku, kpụrụ carbonium carbonate nke na-enweghị isi na mmiri. A na-akpọ usoro a carbon nke slurry. Mmeghachi omume na-eme ka ndị a:

Ca (oh) 2 + Co2 + H2O → cAco3 + (N + 1) H2O

Cyntals carboborals na-agbakọ ọnụ na ibe ya ma ọ bụ ihe ịchọ mma Calcium, na-etolite network cristal network, si otú a na-eme ka ike nke slurry). Na mgbakwunye, n'ihi ntakịrị olu carbonate ma e jiri ya tụnyere calrium hydroxide, isi awọ na-acha ntụ ntụ calcium ntụ ntụ na-eme ka ọ sie ike karị. 3, mgbe etinyere ntụ ntụ na mgbidi, mmiri dị na Puyety na-efunahụ n'ụzọ atọ:

Mmiri ahụ na-efe efe n'elu putty mgbe calcium calcium calcium na White conce tipị na-eme ihe na ntụ ntụ nke dị na mgbidi. 3. Mmetụta nke ihe owuwu ihe dị na ntụ ntụ nke ntụ ntụ Purty:

Ihe kpatara ya maka ebe a na-eme mkpọtụ gụnyere: ọnọdụ mmezi na-eme ka punt kpochie ngwa ngwa ma ghara inwe ike zuru ezu; Elu mgbidi dị elu bụ nkụ, na-eme ka ọ bụrụ na ọ ga-efufu mmiri ọsọsọ; Oke ọkpụrụkpụ nke putty na otu.

Oge Post: Jul-17-2023