Kwanan baya: 1, APR, 2024

An yi imani da cewa mafi girman zazzabi, da ƙarin barbashi ciminti zai ba da adsorb da polycoxylate Wakili. A lokaci guda, mafi girma zazzabi, amma a bayyane yake a bayyane kayayyakin hydration kwasfa zai cinye da polycickboxylate Wakili mai ruwa. A ƙarƙashin tasirin tasirin sakamako, kamar yadda zafin jiki ya karu, da ruwan kankare ya zama mafi muni. Wannan yanke shawara zai iya yin bayani game da abin da ya dace da kankare yana ƙaruwa lokacin da zafin jiki ya karu lokacin da zafin jiki ya sauko lokacin da yawan zafin jiki ya ƙaruwa. Koyaya, yayin gini, an gano cewa ruwan kankanin yanayi mara kyau ne a yanayin zafi, kuma lokacin da yawan zafin jiki ya ƙaru. Wannan ba za a iya bayanin shi da sama da ƙarshe. Har zuwa wannan, ana gudanar da gwaje-gwaje ne don bincika, gano dalilan daliban, kuma suna samar da kewayon zafin jiki da ya dace don kankare.

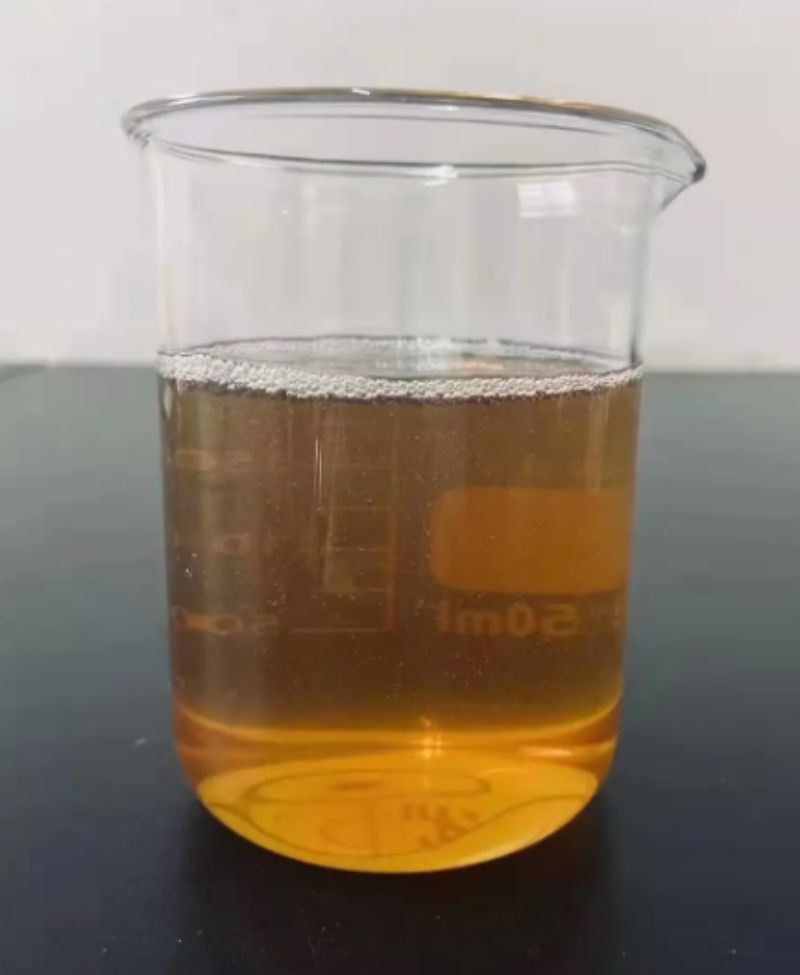

Don nazarin tasirin hadawa da ruwan zafin jiki a kan tasirin watsawa na Wakilin Ruwa na Ruwa. Ruwa A 0 ° C, 10 ° C, 20 ° C, 30 ° C, da 40 ° C, da 40 ° C, da 40 ° C an shirya bi da kokarin strimplastitilitation-Superplitilitation.

Binciken ya nuna cewa lokacin da lokacin fitar da baya ya gajarta, fadada ciminti slurry farko yana ƙaruwa sannan yana raguwa kamar yadda zafin jiki ya karu. Dalilin wannan sabon abu shine yanayin zafin yana shafar ragi na ciminti da kuma yawan kuɗin Superplastizer. Lokacin da zazzabi ya tashi, da sauri farashin manyan abubuwan kwayoyin superplplastritrizer shi ne, mafi kyawun tasirin watsawa zai zama. A lokaci guda, yawan hydring na ciminti yana hanzarta, kuma amfani da wakilin ruwa mai hanzari ta hanyar samfuran hydration yana ƙaruwa, wanda yake rage yawan ruwa. Farkon fadada pastte na ciminti yana shafar tasirin wadannan abubuwan guda biyu.

A lokacin da hadawa ruwa zazzabi ne ≤10 ° C, ragin Superplastizer-Superplitrizer da Cimint din ya karami. Daga gare su, bautar wakilin rage ruwa a kan barbashi ciminti shine ingancin sarrafawa. Tunda adsorption wakili wakili a kan barbashi ciminti yayi jinkirin lokacin da zafin jiki ya ragu lokacin da aka bayyana kashi na ruwa na farko ya ragu, wanda aka bayyana a cikin karancin ciminti slurry.

Lokacin da yawan zafin jiki na haduwa shine tsakanin 20 zuwa 30 ° C, yawan adadin wakilin ruwa da kuma yawan ruwa na sumul na ruwa yana ƙaruwa da ƙari Babu shakka, wanda aka bayyana a cikin karuwa a farkon ruwa na ciminti slurry. Lokacin da haɗuwa da ruwa zazzabi NE ≥40 ° C, adadin sumunti yana ƙaruwa sosai kuma sannu a hankali ya zama abu mai sarrafawa. A sakamakon haka, yawan adadin kwayoyin kwararru na ruwa (farashin adsorption na rage yawan amfani) yana raguwa, kuma ciminti slurry shima yana nuna rashin ingantaccen rage ruwa. Saboda haka, an yi imanin cewa tasirin tasirin ruwa na rage wakili ya fi dacewa lokacin da ruwa ya haɗu tsakanin 20 da ciminti slurry zazzabi shine tsakanin 18 zuwa 22 ° C.

Lokacin da lokacin fitar da-injin yayi tsawo, da fadada slurry ya yi daidai da kammalawa gaba ɗaya. Lokacin da lokaci ya isa, za'a iya tallata wakilin kayan kwalliyar ruwa a kan barbashin ciminti a kowane zazzabi har sai an cika shi. Koyaya, a ƙananan yanayin zafi, ƙasa da rage yawan ruwa-ruwa yana cinyewa don hydration ciminti. Saboda haka, yayin da lokaci ke wucewa, fadada ciminti slurry zai ƙara yawan zafin jiki. Karuwa da raguwa.

Wannan gwajin ba wai kawai ya ɗauki tasirin zazzabi ba, har ma yana kula da tasirin lokaci akan tasirin watsawa na ruwa, yana yanke shawara takamaiman kuma kusa da gaskiyar hanyar. A karshe aka zana sune kamar haka:

(1) A yanayin zafi, tasirin watsawa na rage wakili na polychoxylate Wakili yana da Timeleness na bayyane. Kamar yadda lokacin hadawa ya karu, ruwan sha na slukar da slurry yana ƙaruwa. Yayin da yawan zafin jiki na haduwa da ruwa ya karu, fadada ciminti slurry farko yana ƙaruwa sannan ya ragu. Za a iya zama bambance-bambance masu mahimmanci tsakanin yanayin kankare yayin da ya fito daga injin da kuma yanayin kankare kamar yadda ake zuba a shafin.

(2) A lokacin aikin zazzabi mai ƙarancin zafin jiki, yana dumama ruwa hadawa na iya taimakawa haɓaka ɗakunan ruwa na kankare. Yayin gini, yakamata a biya hankali ga sarrafa zafin jiki na ruwa. Yanayin zafin jiki na slurry yana tsakanin shekara 18 zuwa 22 ° C, da kuma ruwan sama shine mafi kyau idan ya fito daga injin. Hana da sabon abu na rage ruwan daskararru wanda ya haifar da yawan zafin jiki na ruwa.

(3) A lokacin da lokacin fitar da-injin yayi tsawo, fadada ciminti slurry yana raguwa kamar yadda zafin jiki ya karu.

Lokaci: Apr-01-2024